What is a water utility dispatching system: features and advantages

Water utilities operate in difficult conditions: worn-out infrastructure, leaks, pressure fluctuations, rising electricity costs. It is estimated that electricity can account for up to 40% of the operating costs of drinking water systems, and water supply and sewerage systems consume a total of about 2% of electricity. In many countries, electricity accounts for 33-82% of the non-laboratory operating costs of water utilities. Improving energy efficiency could potentially save 20-40% of electricity costs. At the same time, global non-revenue water (NRW) losses are estimated at ~126 billion m³ per year, equivalent to approximately $39 billion in annual losses. Dispatching and telemetry systems are becoming a basic tool.

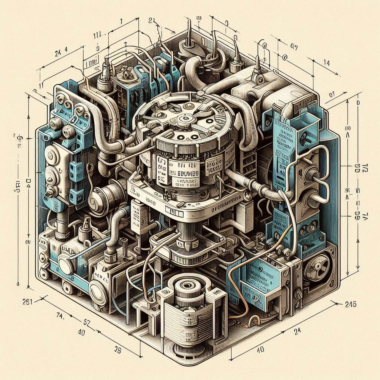

A water utility dispatching system is a set of hardware and software that collects data from facilities, displays it in real time, and allows equipment to be controlled. In fact, it is the “nervous system” of the enterprise, connecting pumping stations, metering stations, reservoirs, and the network into a single mechanism. How does the water utility dispatching system work? During daily operation, the system records events, transmits alarms, and helps to make decisions faster.

Basic functions of engineering network dispatching

Before implementation, it is useful to outline the basic functionality of the system:

- Real-time monitoring of parameters: pressure, level, flow, drive status.

- Control of equipment and start/stop scenarios.

- Notifications, event history, access logs, object map.

- Secure integrations with accounting and city services.

This set of functions gives the control center a complete picture.

Online control of pumping stations and water pressure

The reliability of the system is based on online monitoring of pumping stations and control of units. An important component is the online water pressure control system with configured thresholds and scenarios. For geographically distributed facilities, remote monitoring of pumping stations with alarm prioritization and crew routing is useful. As a result, the number of trips is reduced and response times are shortened.

Remote monitoring and automation of metering

Modern nodes use water metering with data transmission, which simplifies zone control. How to automate water metering? This is solved by combining telemetry, SCADA, and reporting modules: indicators are collected automatically, acts and reports are generated, and imbalances become visible.

How does water supply telemetry work?

Field devices (sensors, meters) transmit readings to controllers, then via communication channels to a server or cloud, where data is stored, analyzed, and visualized. In essence, this is the answer to “what is telemetry in water supply” — it is a technology for continuous collection and processing of parameters.

Collecting data from water meters

Mechanical and ultrasonic devices are most commonly used. How do ultrasonic water meters work? They measure the flow rate based on the time difference between ultrasonic pulses traveling “against” and “with” the flow (transit time). This is a lossless technology with high accuracy and simple maintenance. What data does water supply telemetry collect: flow, volume, pressure, level, electrical equipment status, emergency events.

Real-time transmission of indicators

Data is transmitted via Ethernet, GSM/3G/4G, or LPWAN, depending on the availability of communication and power consumption. First, security and reliability requirements are agreed upon. After selecting the channel, buffering and recovery from failures are provided so that the history is not lost.

Examples of SCADA use in water utilities

SCADA handles control, archiving, and analytics tasks. That's why the question “what is a SCADA system in a water utility” is relevant in connection with case studies: the introduction of modern telemetry and SCADA can reduce leaks and speed up recovery after accidents. In practical cases, operators found over a thousand leaks and dozens of breaks in a few months thanks to smart sensors and analytics.

Water metering and analytics

Metering is not just about paperwork. It is the basis for financial discipline and repair planning. That is why it is useful to explain “what a water metering station is” — it is a measuring point with a meter, sensors, and a controller that records consumption at the zone boundary or at the facility entrance.

Analysis of water consumption by zone

Zonal analysis shows where imbalances occur and suggests how to reduce water losses in the water utility:

- Setting up metering zones and “night” consumption comparisons.

- Detecting leaks by consumption and pressure profiles.

- Controlling pressure and pump start profiles.

Technological approaches help answer the question “how to reduce water losses in public utilities.” According to estimates by the IWA/WHO/World Bank, reducing NRW represents a global reserve of tens of billions of dollars per year.

History of indicators and reporting

The system stores a complete history, generates daily/monthly reports and KPIs. How the telemetry system works: data is collected automatically, verified and converted into performance indicators. It is worth emphasizing that a permanent archive is the key to auditing and informed management decisions.

Integration with Excel, 1C, and other systems

Telemetry must be integrated with the IT landscape of the enterprise. Many projects use “telemetry integration with Excel and 1C,” as well as GIS and billing. Before the lists, the exchange format is confirmed, and after, the data is checked for correctness so that the automation of reporting in the utility sector works stably.

Advantages of water utility automation

Careful implementation brings measurable results. The key advantages of water utility automation are already evident in the first quarter of operation, if collection and analytics are set up correctly.

Reduced water and energy losses

Pump energy consumption is the main cost factor. In some networks, pumps consume up to 90-95% of the water utility's total electricity. Pressure control algorithms, rapid leak detection, and optimized start-up schedules reduce bills and imbalances. This set of solutions answers the question of “how to reduce water losses in networks” and provides a noticeable economic effect.

Control of accidents and shutdowns

Real-time automatic alerts, response procedures, and event logs enhance the monitoring of accidents and shutdowns. Before the lists, acceptable limits and responsible persons are configured, and after that, incidents are analyzed to reduce downtime.

Increased transparency of enterprise operations

A single dashboard, access logs, complete history, and integrations are the direct benefits of engineering network dispatching. Increased transparency of enterprise operations is provided by a single dashboard with KPIs, access logs, complete event history, and open integrations with 1C/ERP, GIS, billing, and BI. Role-based access and action auditing establish accountability, standardized reports reduce manual errors, and a transparent incident notification procedure with defined SLAs makes responses predictable. Contractor control is based on work chronology and cost comparison with the plan. Transparent processes simplify communication with stakeholders and help protect investments.

Control of accidents and outages: real-life cases

Automatic real-time alerts, response regulations, and event logs enhance the monitoring of accidents and outages. Real-life examples of implementation:

- A water supply company uses monitoring and remote control: it regulates pressure according to a schedule, emergency alerts significantly speed up response times, and analytics optimize maintenance plans and reduce fuel costs. Intermediate pressure control detects leaks, and pressure and outages can be controlled remotely during repairs.

- A gardening cooperative has installed level control in reservoirs and a remote pumping station (~3 km). The system operates automatically, and authorized personnel can manually control the pump on site for maintenance, repairs, or peak watering.

- A pharmaceutical factory monitors meters: manages procurement and disposal costs, controls pressure and temperature for processes, transmits data to external systems, and generates automatic reports for responsible persons.

Centralized monitoring and remote control increase the reliability and quality of water supply, reduce response time and operating costs.

Increased transparency of the enterprise's operations

A single dashboard, access logs, complete history, and integrations are the direct benefits of engineering network dispatching. Increased transparency of the enterprise's operations is provided by a single dashboard with KPIs, access logs, complete event history, and open integrations with 1C/ERP, GIS, billing, and BI. Role-based access and action auditing establish accountability, standardized reports reduce manual errors, and a transparent incident notification procedure with defined SLAs makes responses predictable. Process transparency helps protect investments.