The municipal enterprise “Goravtodor” has implemented the task of “Protection and Management of Street Lighting”

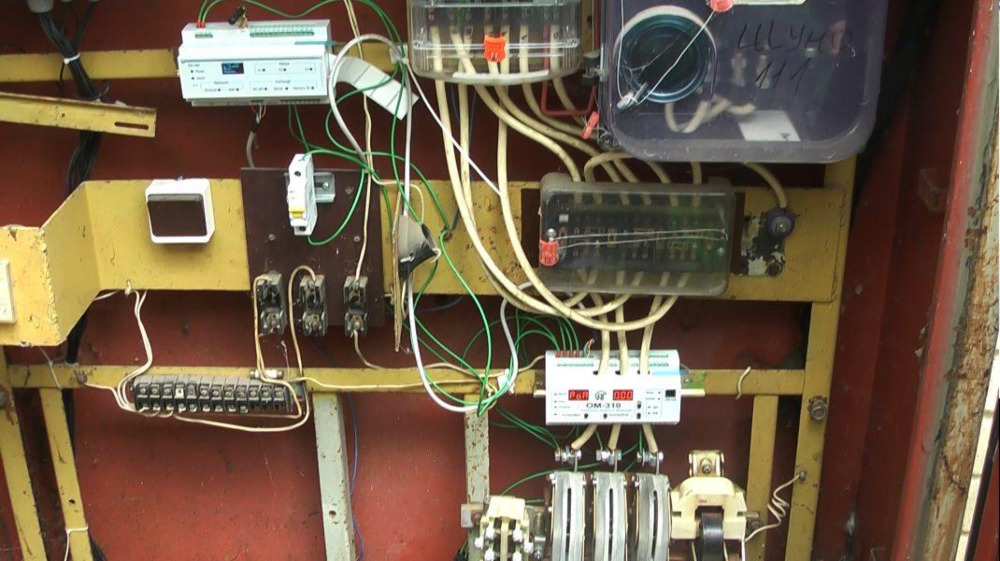

The power limiter OM-310 performs the following functions: voltage control (phase and line), current and power control, accounting for total, active, and reactive energy, management of two loads, protection against current, power, phase imbalance, and voltage. OM-310 collects information about the electrical network and transmits it via the open Modbus RTU protocol for further analysis.

Similarly, the set includes EM-486, a remote access controller for manual control and dispatcher monitoring of street lighting control panels, which receives data from OM-310 and transmits it to a cloud server. This setup allows for:

– Monitoring the operation of serviced points via convenient and intuitive web-based dispatcher panels;

– Creating a notification system for maintenance personnel and minimizing downtime;

– Collecting all reporting information through an automated data collection system;

– Adjusting equipment operation and analyzing statuses without on-site visits;

– Receiving detailed history and XLS reports on energy consumption and other vital parameters for system analysis;

– Providing individual users with access to real-time visualization of the technological process and partial access to necessary reporting and control;

A similar task was implemented by the municipal enterprise “Misksvitlo.” This time, it was necessary to obtain information about the electrical network status at a 0.4 kV two-transformer substation.

For this purpose, OM-310 units were installed at the input and output cells for each feeder of the 0.4 kV switchgear via external current transformers of the appropriate rating.

And all of them are sequentially connected to the EM-486 remote access controller.

Now the dispatcher, sitting in their chair, can observe complete information about what is happening at the transformer substation, including:

- Active voltage (phase, line) on each phase (input and output feeders);

- Active current and power of each phase;

- Energy consumption on each feeder;

- Status of fuses on outgoing lines;

- Monitoring door openings in the 0.4 kV switchgear;

- Temperature in the 0.4 kV switchgear room;

- Data collection and plotting of electrical load and consumption graphs;

- SMS notifications or auto-dialer for emergency situations at the site.