What is a refrigeration equipment monitoring system and how does it work?

Cold is not just a ‘low temperature’ but a controlled process. Businesses with a cold chain lose money every time parameters go out of range and staff find out about it too late. How does the system work, what components are needed, and how can you control the temperature in a cold store without unnecessary costs?

What is a cold room monitoring system?

A monitoring system is a combination of sensors, controllers and software that collects all indicators, including humidity, door status and power supply, and transmits them to a server or the cloud. It records data, notifies of deviations, generates reports and an event log. This approach reduces the risk of product spoilage and helps to pass audits.

How the monitoring system works

How does temperature monitoring in refrigerators work? Sensors transmit readings to the controller (PLC/recorder) via Modbus or 4–20 mA/pulse analogue inputs. The communication module sends Ethernet/Wi-Fi/GSM data to a server or cloud, where it is stored, graphs are built, and limits and notifications (Email/Telegram/SMS) are configured.

Why is temperature control necessary in a cold storage facility?

Firstly, for product safety and regulatory requirements. Secondly, for savings: the earlier a deviation is detected, the less write-offs and energy consumption. Thirdly, for auditing: systematic recording of all events provides answers to the inspector's questions.

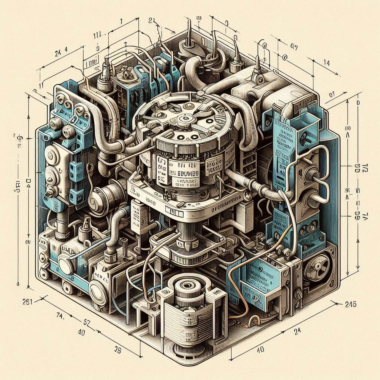

Main components: sensors, controllers, communication modules

The refrigerator monitoring system is based on the integration of these elements for accurate real-time data collection and processing:

- Sensors: temperature (PT100/DS18B20), humidity. How do door opening sensors work in refrigerators? These are magnetic/reed pairs that record the fact and duration of opening.

- Controllers/recorders: sensor polling, local archiving on SD, thresholds, relay outputs.

- Communication: Ethernet, Wi-Fi, GSM/LTE; Modbus TCP/RTU, MQTT, HTTPS protocols.

This structure ensures uninterrupted operation and quick response to deviations.

Temperature and humidity control

Temperature is a basic parameter, but in many cases humidity is also critical: excessive condensation damages labels and packaging, while overdrying affects the quality of fresh products. Comprehensive monitoring keeps both parameters within acceptable limits.

How does mode control work in refrigerators?

The algorithm is simple: continuous measurements + acceptable limits + hysteresis + notification delay. This minimises ‘false’ alarms during defrosting or brief door opening. This is how control in refrigerators works in practice – consistently and predictably.

Parameter standards for food storage

Typical temperature ranges for food storage in cold stores:

- fresh meat/fish: 0…+2 °C;

- dairy products: +2...+6 °C;

- ready meals: +2...+4 °C;

- frozen products: −18 °C and below.

Adhering to these ranges is the easiest way to avoid spoilage of products in refrigeration equipment.

Monitoring humidity and its impact on product quality

Humidity affects shrinkage, product structure and appearance. Monitoring and graphs help to see the connection between ‘defrost cycle → peak humidity → condensation’ and adjust settings.

Alerts and temperature log

The system warns of deviations, and the log proves that the user acted correctly. This is the core of operational responsibility and compliance.

How to set up alerts for parameter deviations

How to set up alerts when the temperature goes out of range:

- set upper/lower thresholds and hysteresis;

- add a 5-10 minute delay to filter out short fluctuations;

- set up Email/Telegram/SMS + backup push channel;

- route alarms: next shift → technician → manager.

This approach minimises false alarms and ensures quick problem solving.

How to keep a temperature log in cold rooms?

Keep an automatic log with signatures: chamber, probe, time, value, event (door/defrost/alarm). How to store the temperature history of refrigerators in a convenient form for checks? This is exactly what a log is for.

How long to store temperature monitoring data?

The food industry usually adheres to the principle: no less than the shelf life of the batch + 1 year. Therefore, monitoring data must be stored for at least 12 months, preferably 24. This also facilitates the investigation of incidents.

Standards and requirements

Mode management is part of food safety systems. HACCP and international standards apply here.

HACCP requirements for temperature control

HACCP requirements for parameter control include the identification of critical control points, tolerance limits, tracking, corrective actions and verification. Thanks to monitoring, the requirements for accounting and traceability are met automatically.

ISO, GMP and GxP standards for refrigeration equipment

A common question is: what are the ISO standards for monitoring refrigerators? Usually, the focus is on ISO 22000 (food safety), ISO 9001 (quality), and in the pharmaceutical industry, GMP/GxP (good practices), validation of data loggers and processes.

The importance of logs for auditing

Logs are the key to evidence. The importance of temperature logs for auditing: users can quickly show graphs, alarms, staff responses, and prove process control.

Practical tips for warehouse and retail owners

A well-organised checklist will help you get started quickly and reduce risks.

How to avoid product spoilage:

- Calibrate probes every 6–12 months.

- Keep limits close to standards, but with a margin of 1–2 °C.

- Track door openings: train staff to close them quickly – this is a free way to reduce losses from product spoilage.

Recommendations for choosing sensors and monitoring systems:

- Sensors used for temperature control: PT100 (accurate/stable), digital sensors, capacitive sensors for humidity.

- Communications: use Wi-Fi and GSM as backups for each other.

- Architecture: local and cloud solutions. Local is faster and autonomous, while the advantages of the cloud are ‘anywhere’ access, scalability, and redundancy. If in doubt, choose a hybrid.

- Integrations: what is API integration – it is the exchange of events/data with ERP. You can connect the system to 1C or SAP via REST/MQTT gateways.

- Continuity: the importance of backup power for control – UPS for the controller/communication. What to do when the refrigerator power is turned off – instant notification + action scenario.

- Regulation: ISO standards for monitoring refrigeration equipment, GMP and GxP standards for product storage – include them in the technical specifications.

Examples of effective monitoring systems:

- Local recorder with Ethernet and SD for archiving: graphs, thresholds, SNMP/MQTT – a reliable ‘backbone’ of the warehouse.

- Cloud platform with mobile app and push notifications – quick response from staff.

- Combined solutions with door, defrost and energy consumption control – these are real examples suitable for both pharmacies and retail.

Such systems increase operational efficiency and ensure continuous product protection.

Short answers to frequently asked questions

Concise answers to the most common questions about refrigeration equipment monitoring systems to help you quickly understand the key aspects:

- What are the ways to control cold rooms remotely: web interface or cloud application.

- Which is better: a cloud or local server for tracking – it depends on the SLA/internet, a hybrid provides a balance.

- Requirements for the cold chain: continuous monitoring, documentation, response to deviations.

- How much does it cost to implement the system: depends on the cost of sensors/channels and the network. Consider the TCO, not just the initial price.

- Data security in cloud solutions: TLS, role-based access, backups.

A refrigeration equipment monitoring system is an easy way to reduce losses, improve product safety and comply with HACCP, ISO, GMP/GxP requirements. Continuous monitoring, alerts and event logs ensure fast response and transparent reporting.